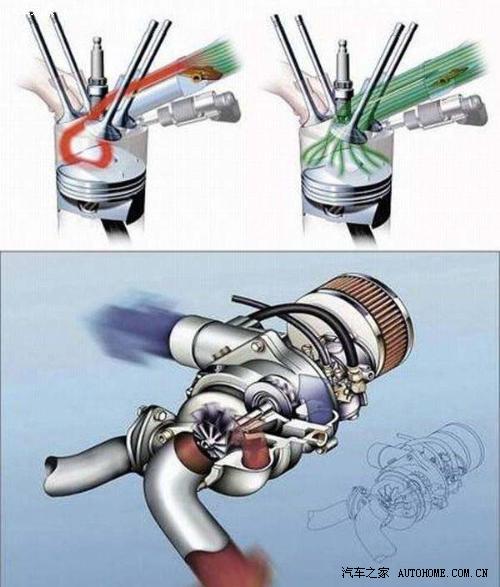

in the energy and environmental requirements increasingly stringent Today, even such a multi-point fuel injection technology can not meet the requirements of the people, so more precise fuel injection technology was born, that is, direct injection technology.

is the in-cylinder direct injection fuel nozzle is mounted in the cylinder, fuel is injected directly into the cylinder is mixed with the intake air. Injection pressure is further improved, more detailed fuel atomization, truly precise control of fuel injection and proportionally mixed with the intake air, and to eliminate the disadvantages of the out-cylinder injection. Meanwhile, the special design of the nozzle position, the spray pattern, the intake air flow control, and the piston crown shape, so that oil and gas throughout the cylinder can be sufficiently uniformly mixed, so that fuel combustion, higher energy conversion efficiency.

However, direct injection technology is not invincible, because from an economic perspective, the use of direct injection in addition to the oil supply system must spend a greater cost in the development process, in the parts of a complex and sophisticated, the price components also is more expensive than conventional oil supply system, so these are the future of direct injection engine yet to overcome the elements.

TSI

in foreign 1.4T Volkswagen Scirocco 1.4T engine as well as import, on behalf of the TSI is Twincharger Fuel Stratified Injection these words acronym, by letter surface can be understood as meaning a dual plenum + + injection stratified combustion means. TSI engine is based on FSI technology, the installation of a turbocharger and a supercharger, in view of the characteristics of the turbocharger and the supercharger, the supercharger can be provided to the engine from the idling start supercharging effect, to make up for the shortcomings of the delay turbocharging system, so the TSI engine is a form of high efficiency, it would be perfect unity power performance and fuel economy of the fuel.

“Twincharger Fuel Stratified Injection”

However, the domestic production of 1.4T supercharged engine is castrated and stratified burning, onlyRetain turbocharging and direct injection.

while the mass 1.8 / 2.0TSI ldquo; TSIrdquo; represents a Turbo Fuel Stratified Injection, by the letters can be understood as meaning surface turbocharger + + direct injection stratified combustion means, but domestic then eliminating the need for stratified combustion.

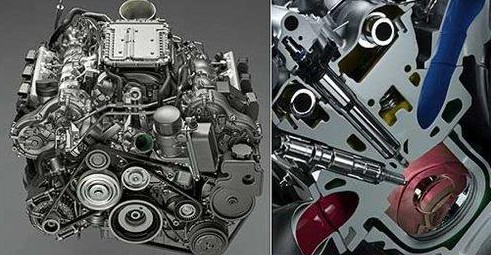

TFSI FSI Volkswagen / Audi gasoline direct injection technology, FSI may be a fuel directly into the combustion chamber, reduces the heat loss of the engine, thereby increasing the power output and reduced fuel consumption, for fuel economy and dynamic performance have helped. FSI engine is turbocharged TFSI (T), the abbreviation TFSI, Audi series models will be generally so called, and the popular series direct-injection engine with a supercharger referred to as the TSI. However, because of the problem of domestic oil, Audi TFSI does not use stratified combustion technology.

FSI

FSI, literal translation of the word it represents as the fuel stratified injection, it is a sign of the code Volkswagen direct injection engine. So FSI engine What are the benefits? It’s loaded car can bring us what kind of surprise?

compared to those of the gas injected into the engine intake manifold, the main advantage FSI engine are: good dynamic response, can improve the power and torque while reducing fuel consumption.

“FSI is the main public push engine technology.”

In theory, FSI engine has at least two combustion modes: stratified combustion and homogeneous combustion , it was also divided into the homogeneous combustion mode and a homogeneous lean mode homogeneous combustion mode. Fuel Stratified Injection FSI represents the meaning from the point of view, should be the essence of the stratified combustion characteristics FSI engine, but it can also be understood as a starting point for research and development and infrastructure.

stratified combustion has the advantage of high thermal efficiency, low throttling losses, limited as much as possible of the fuel is converted into work energy. The stratified combustion mode, the throttle valve is not fully opened, to ensure that the intake pipeWithin a certain degree of vacuum (and may control the exhaust gas recirculation device canister, etc.). In this case, the engine torque is dependent on the size of the fuel injection amount, the intake air amount and the ignition advance angle has little relationship.

In the stratified combustion mode during an intake throttle valve opening degree is relatively large, reducing the portion of throttling losses. Key intake process is disposed in the intake manifold a replica replica open up (the principles of the nature of the actual models may vary) is sealed at the intake manifold, so that the intake air accelerated by, the Omega; shaped piston top fitting, complementary intake swirl.

stratified combustion when the fuel injection time in the top dead point before 60deg; 45deg ;, before top dead injection time has a great influence on the formation of air-fuel mixture, fuel is injected in the pit of the piston top, spray a fuel vortex is formed in conjunction with the intake air-fuel mixture. Mixture formation occurs at a crank angle 40 deg; to 50 degrees; the range, if less than this range, the mixed gas can not be ignited if it exceeds, it becomes a homogeneous state. Stratified combustion air-fuel ratio is generally between 1.6-3.

When the ignition, only around the spark plug is preferably a mixed state of gas is ignited, when the fresh air and the gas around the exhaust gas recirculation is formed from a well insulated protection, reducing the cooling cylinder arm, improved thermal efficiency. Ignition timing control is also very important, the compression only in a very narrow range ending process.

“video presentation stratified combustion”

the homogeneous lean mode mixture formation for a long time, uniform combustion , by precisely controlling the fuel injection, to achieve a lower concentration of the mixture. Ignition timing broad range of homogeneous lean, good fuel economy.

the lean homogeneous combustion and stratified same intake process, oil extended mixing time, to form a homogeneous mixture. Combustion occurs throughout the combustion chamber, the ignition timing is not required for stratified combustion less stringent. A lean homogeneous air-fuel ratio is greater than 1.

“FSI engine configuration diagram”

the homogeneous combustion can be chargedSub play good dynamic response, high torque and power characteristics. Homogeneous combustion during the intake throttle position determined by the accelerator pedal, a replica of the location in the intake manifold depending on circumstances. Among isochronous load, a replica is still closed, favors the formation of a strong cyclonic flow into, conducive to the formation of mixed gas atomization. When the high speed high load, replica opened, the intake air amount is increased, so that more air is involved in combustion. Fuel injection homogeneous combustion, and the combustion gas mixture is formed with substantially the same as the homogeneous lean mode. The homogeneous combustion air-fuel ratio is less than or equal to 1.

above three FSI engine combustion state is unique to combustion control mode, but some aspects still remain in terms of theoretical advantages. Now Audi FSI engine also released worldwide have adopted the homogeneous combustion mode, this does not mean stratified combustion can not be achieved, but only that the cost or timing of implementation of stratified combustion is not yet ripe. Mainly in the stratified combustion with a lean mixture, to improve the in-cylinder temperature also increases nitrogen oxides such harmful emissions. For lean burn, Common catalytic conversion of nitrogen oxides is difficult to clean and requires the addition of a NOx reduction catalytic converter, and adds to the burden of space and cost. In addition, the high sulfur content of gasoline at this stage this is very damaging to catalytic converters, and therefore there is the transformation of oil refining equipment, improve fuel quality and cost.

“Benz CGI engine also uses direct injection technology.”

is not a stratified combustion will not let FSI engine the original advantage gone? the answer is negative. Even without the application of stratified combustion, FSI can improve the compression ratio of the engine as well as to reduce the amount of residual oil combustion characteristics. FSI engine with direct injection, gasoline evaporated in the cooling effect is generated inside the cylinder, thus reducing the likelihood of knocking, it may be appropriate to enhance the compression ratio. When blended with swirl intake valve timing can not obtain a good combustion of the residual oil re-use. In this way, FSI engine still greater as increased power, lower fuel consumption.

FSI effect produced by the engine can be seen from the engine Audi indicators released by the company. 3.2 l and 4.2 l FSI FSI example, contrast the previous model were 3.0 liters and 4.2 liters of gasoline. The power, 3.2 liter FSI 257 horsepower engine, than the original machineType 218 horsepower 39 horsepower, 4.2-liter FSI 350 horsepower engine 15 hp 335 hp compared to the original model; on the maximum torque, 3.2 liter FSI of 330 Nm 290 Nm of the original model, 420 Nm 4.2 l FSI 440 of the original models.

FSI effect produced by the engine can be seen from the engine Audi indicators released by the company. 3.2 l and 4.2 l FSI FSI example, contrast the previous model were 3.0 liters and 4.2 liters of gasoline. The power, 3.2 liter FSI 257 horsepower engine, than the original machineType 218 horsepower 39 horsepower, 4.2-liter FSI 350 horsepower engine 15 hp 335 hp compared to the original model; on the maximum torque, 3.2 liter FSI of 330 Nm 290 Nm of the original model, 420 Nm 4.2 l FSI 440 of the original models.

“the public in the domestic production of stratified combustion engine is canceled, the only remaining direct injection”

SIDI

Universal fuel straight jet technology, code-named SIDI, SIDI is spark ignition direct injection Abbreviation, literally translated as spark ignition direct injection.

and the general principle of the realization of the direct injection engine no different: to provide a camshaft-driven fuel pump to supply high pressure fuel system, the high-pressure fuel common rail injector directly into the cylinder, the ignition timing can be accurately controlled, and fine and high-pressure jet nozzle design is to ensure the accurate calculation of the fuel injection amount. After direct injection technology to replace the traditional MPFI (multi-point EFI) technology, the engine rotational speed at a low combustion efficiency is further improved.

“6-hole injectors”

In addition, a common technique relies on the cylinder SIDI homogeneous combustion to improve efficiency, and without the use of stratified lean combustion technology. Due to restrictions on domestic oil, the introduction of domestic direct injection engine not use stratified combustion, general SIDI is no exception. But do not use stratified combustion SIDI engines also have the advantage of not picky eaters, the official product manuals also did not make any special maintenance requirements of the SIDI engine, which is its biggest advantage compared to where the public system direct injection engine.