1. Introduction

Engine

Engine (English: Engine, motor), also known as the engine, is capable to be converted to other forms of energy mechanical energy, comprising an internal combustion engine (gasoline engine), an external combustion engine (Stirling engine, a steam engine, etc.), such as a motor. The internal combustion engine is generally convert chemical energy into mechanical energy. It applies to the power generating means may also refer to the entire machine comprising a power unit.

Here is the main heat engine.

is in a car engine to generate power. It fuel combustion heat into mechanical power, the power output from the crankshaft of the engine outwardly, is the source of the required power cars. Modern automobiles use more of the reciprocating engine.

Depending on the fuel and ignition can be divided into the form of gasoline or diesel, or hydrogen gas, natural gas, LPG fueled engine, the combustion in the form of its small gasoline engine differences.

The division of the work cycle of the piston stroke characteristics, can be divided into two-stroke and four-stroke engines.

2, the origin

engine was first born in the UK, so the concept of the engine is derived from the English, its meaning is that the kind of “mechanical device to generate power.” As technology advances, people are constantly developed different uses various types of engines can be divided into: internal combustion engines, external combustion engine, electric motor three categories. This term describes the heat engine to the combustion of some fuel to generate power.

3, the development

the internal combustion engine

the internal combustion engine

Development of the engine has experienced two stages and an external combustion engine.

The external combustion engine

It means that the fuel in the external combustion engine, combustion engine such productionStudents energy into kinetic energy, Watt steam engine is a typical external combustion engine, when a large amount of heat generated when the coal combustion can heat water into a large amount of water vapor, will produce a high pressure, high pressure and this in turn pushes the mechanical work , thus completing the transformation of heat energy to kinetic energy.

the internal combustion engine

This type of external combustion engine and the biggest difference is that its combustion of fuel therein. Very many types of internal combustion engines, our common gasoline engine, diesel engine is a typical internal combustion engine. Assembled on our unusual rocket engine and aircraft jet engines also belong to the internal combustion engine. However, due to the different power output, both before and after two and there is a huge difference. In general, the use of on the ground more than the former, used in the air more than the latter. Of course, some car manufacturers for the purpose of creating a new world speed record car, the car is also used coat jet engine, but it is always very special case, there is no applicability for mass production.

The gas turbine

in addition to the gas turbine, the working characteristic of this combustion engine is generating pressure gas, high-pressure gas turbine blades driven in rotation, to output power. Gas turbine using a wide range, but because it is difficult to finely adjust the power output, so cars and motorcycles rarely used gas turbine, gas turbine used only part of the car fitted.

4, the

engine displacement

engine displacement

The most common one engine parameter — engine displacement. Engine displacement is the sum of the working volume of each cylinder of the engine, generally expressed in liters (L). And it refers to the working volume of the cylinder of the piston from the upper dead point to the lower dead point swept volume of gas, also known as the displacement cylinder, which depends on the bore and piston stroke. Engine displacement is a very important engine parameters, it is more than the number of cylinder bore and more representative of the size of the engine, it is closely related to the displacement of many indicators of the engine. Generally, the larger the displacement, the larger the engine output power.

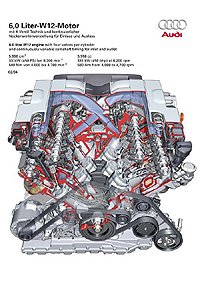

often word “L4”, “V6”, “V8”, “W12” and other automotive engine data column seen, which are expressed in the form of engine cylinders are arranged andNumber of cylinders. Number of cylinders with a common automobile engine 3 cylinder, 4-cylinder, 6-cylinder, 8-cylinder, the cylinder 10, the cylinder 12 and the like.

in the same bore, the more the number of cylinders usually larger displacement, the higher power; in the case of the same engine displacement, the more the number of cylinders, the smaller bore, the engine speed can be improve, so as to obtain a larger increase power.

on the “cylinder arrangement forms” this important parameter, typically 5 cylinder engine cylinder to use more or less arranged in line, are common in most cars L4 engine middle and low, i.e., inline 4-cylinder. In addition, a small number of in-line six-cylinder engine with arrayed.

the energy efficiency of the engine

Now the energy utilization efficiency is not high (Deng Yu et al., 1994), much waste. Classic heat engine acting the way, the energy efficiency of useful work only 25 percent (1/4), also the highest one-third (33.3 percent), while 75 percent (3/4) of one hundred percent of the energy, or 66.67 percentage (2 / 3) is wasted as unwanted heat out. Another accident, “Banks heat engine” is not using a memory alloy fuel efficient engine does not consume electric power.

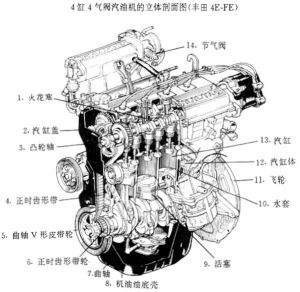

5, the structure

Cylinder

Cylinder

body skeleton composed of an engine, a mounting base of the engine agencies and systems, which inner and outer mounting of all major components and accessories of the engine, subjected to various loads. Therefore, the body must have sufficient strength and rigidity. Organism group is mainly composed of a cylinder block, crankcase, cylinder head gasket and a cylinder head and other parts.

The cylinder block

and a cylinder block of the water-cooled engine is often cast in one piece to the crankcase, the cylinder block is called – the crankcase, the cylinder block may also be referred to. Generally gray cast iron cylinder block cast, the upper cylindrical cavity of the cylinder block is called a cylinder, the lower half of the crankcase supporting the crankshaft, which crankshaft lumen spatial movement. Cast in the cylinder body has many ribs, the lubricating oil passage cooling water jacket and the like.

The cylinder block

The cylinder block

according to different cylinder arrangement, the cylinder block can be divided into separateType, V-type and opposed three.

crankcase

lower cylinder block portion for mounting a portion called the crankshaft crankcase, crankcase and a lower crankcase points on the crankcase. Crankcase is integrally cast with the cylinder block, the crankcase for storing lubricating oil, and closing the crankcase, also called pan (Figure 2-6). Sump force is very small, typically using a thin steel stamping, which depends on the shape and arrangement of the overall capacity of the engine oil. Oil sump built with stabilizing baffles, to prevent the oil surface when the vehicle is moving Britain excessive fluctuations. Sump at the bottom is also equipped with the oil drain plug, drain plug usually put on with a permanent magnet to adsorb metal chips lubricating oil, to reduce engine wear. Joint surface between upper and lower crankcase padded to prevent leakage of lubricating oil.

The cylinder head

is mounted in a cylinder head above the cylinder block, a cylinder and sealed from an upper portion defining the combustion chamber. It is often in contact with high pressure gas, thus subjected to high thermal and mechanical loads. The cylinder head is made of water-cooled engine with a cooling water jacket, cooling water hole and a cooling water hole of a cylinder head in communication with the end face. Use of recycled water to cool the high temperature portion of the combustion chamber and the like.

The cylinder head is generally gray cast iron or alloy cast using cast, good thermal conductivity of aluminum, help to improve the compression ratio, the aluminum cylinder head is adopted in recent years more and more.

is an integral part of the cylinder head of the combustion chamber, combustion chamber shape greatly influence the work of the engine, due to the different combustion gasoline and diesel engines, the cylinder head portion of a larger difference in composition of the combustion chamber. Gasoline main combustion chamber in the cylinder head, a combustion chamber of the diesel engine and the main pits top of the piston. Here only the combustion chamber of gasoline engine, diesel engine and a combustion chamber in a diesel supply system in the introduction.

Three types of combustion chamber Cylinder head gasket

Three types of combustion chamber Cylinder head gasket

In the cylinder head gasket installed between the cylinder head and the cylinder, its purpose is to ensure the sealing of the cylinder head and the cylinder block contact surface to prevent leak, leaks and oil spills.

The cylinder head gasket materials have a certain elasticity, can compensate for unevenness of the bonding surface, to ensure sealing also have good heat resistance and pressure resistance, without burning at high temperature and pressure, is not deformation. Current application is copper – cotton configuration of the cylinder head gasket, since copper – Cotton flange at the cylinder head gasket has three copper, when pressed than asbestos deformation. Some engine also uses a woven asbestos CenterThe outline of a screen or perforated steel skeleton, both surfaces of asbestos and rubber adhesive pad pressed into the cylinder.

6, Category

in accordance with the intake Category

in accordance with the intake Category

Many classification engine, according to different classification methods can be divided into different types of internal combustion engine, let Let’s look at how the internal combustion engine is classified.

Classification according intake

in accordance with the internal combustion engine with a pressurized air intake system can be divided into naturally aspirated (non-supercharged) engine and an intake force (supercharged) engine. Gasoline often used naturally aspirated; diesel engine to increase the power with a supercharged employed.

Cylinder arrangement according to Category

in accordance with the engine cylinder arrangement can be divided into single-row and double row. Each single cylinder engine arranged in a generally vertically arranged, in order to reduce the height of the cylinder is also sometimes arranged inclined or even horizontal; the double row of the engine cylinders arranged in two rows, sandwiched between the two angle lt; 180 ° (typically 90 °) referred to as V-type engine, if the angle between the two is called = 180 ° opposed engine.

in accordance with the number of cylinders Category  in accordance with the number of cylinders Category

in accordance with the number of cylinders Category

according to the engine cylinders may be divided into a different number of cylinder engines and multi-cylinder engine. Only one cylinder of the engine is called a single cylinder engine; two or more cylinders of the engine is called a multi-cylinder engine. The cylinder, three-cylinder, four-cylinder, five-cylinder, six-cylinder, eight-cylinder, etc. are twelve-cylinder multi-cylinder engine. Modern car engine with four-cylinder, six-cylinder, eight-cylinder engine.

The cooling manner Category

in accordance with the engine cooling can be divided into water-cooled engine and air-cooled engine. Water-cooled engine with a cooling liquid is circulated in the cylinder block and cylinder head cooling jacket for cooling water as a cooling medium; and the use of air flow to the engine is the cylinder block and the cylinder head between the outer surface of the air as a cooling medium fins for cooling. A water-cooled engine cooling uniform, reliable, good cooling effect, are widely used in modern vehicle engines.

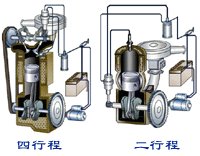

line in accordance withCheng Category  according to a Trip

according to a Trip

the internal combustion engine in accordance with the number of strokes needed to complete the work cycle of a four stroke internal combustion engine and can be divided into two-cycle engines. The two crankshaft revolutions (720 °), vertical reciprocating movement of the piston in the cylinder four stroke, a complete working cycle is referred to as a four-stroke internal combustion engine; the revolution of the crankshaft (360 °), vertical reciprocating the piston within the cylinder sports two trips to complete a work cycle internal combustion engine called two-cycle engines. Automobile engines are widely used four-stroke internal combustion engine.

according to the type of fuel

in accordance with the engine fuel can be divided into different gasoline and diesel engines. An internal combustion engine using gasoline as a fuel is called a gasoline engine; diesel engine using diesel fuel is called. Comparison of gasoline and diesel engine have different characteristics; gasoline high speed, low mass, low noise, easy starting, low manufacturing cost; diesel engine compression ratio, high thermal efficiency, economy and emission performance are better than gasoline.

in accordance with applicable object class heavy-duty truck engines, light truck engines, passenger car engines, construction machinery, engines, agricultural engines, marine engines, power generation engines.

7, working principle

two-cycle engine  Two-Stroke Engine

Two-Stroke Engine

Each two-stroke working cycle of the engine, the crankshaft is rotating 360 i.e. one week, two vertical stroke of the piston is completed.

two-stroke diesel engine during operation and two-stroke gasoline engine, with the difference that: into the diesel engine cylinder air is pure. Due to the two-stroke diesel engine of the economy and poor sewage serious in recent years has become out of the car. In this presentation only works two-stroke gasoline engine.

There are three holes in the engine block, i.e. the intake and exhaust ports and the vent hole, three holes are closed by the piston at a given time. It communicates with the carburetor intake port, the combustible mixture through the inlet hole inflow crankcase, and then into the cylinder from the vent hole; and the exhaust gas from the vent holes.

which includes two stroke operating cycle:

a first stroke: the piston moves upward from the bottom dead center, the three air holes are closed, above the piston, the cylinder has entered the gas mixture is compressed; the crankcase below the piston due to the volume increase large, a certain degree of vacuum, when the intake port is exposed, the combustible mixture from the carburetor inflow of crankcase through an inlet.

2 second stroke: the piston to the compression top dead center, spark plug flash igniting the combustible gas mixture, the high temperature and high pressure gas expander, to push the piston down for power. Piston intake port closed down for power, it is compressed in the sealed combustible gas mixture in the crankcase; when the piston is near the bottom dead center Kongkai Qi Bu exhaust gas, out of the exhaust gas; Kongkai Qi ventilation Subsequently, by preloading the combustible mixture person red cylinder, purge gas, process for ventilation. This process continues until the next stroke of the piston shifts, three completely closed pores.

8, technical analysis

type of engine characteristics  turbo engine (Turbo)

turbo engine (Turbo)

is a technique for improving engine supercharging intake the method of gas capacity. It in advance into the cylinder gas compressed by using a dedicated compressor, to improve the density of the gas into the cylinder, the intake air amount is increased, to better meet the needs of the fuel combustion, so as to improve the engine power.

Advantages: without increasing the engine displacement, can greatly improve the power and torque

Disadvantages: work turbo lag, and high maintenance costs.

Representative models: suteng Bora 1.8T 1.8T 1.8T Touran Passat 1.8T Audi A4 1.8T / 2.0T Audi A6 2.0T

supercharged engine (Supercharger) [123 ] supercharger compressor is directly driven by the crankshaft of the engine, it is the advantage of good response. But it needs to consume part of the energy itself, and therefore can not generate particularly strong mechanical supercharger driving force, especially at high speeds, which affects the increase the engine speed.

supercharged engine (Supercharger) [123 ] supercharger compressor is directly driven by the crankshaft of the engine, it is the advantage of good response. But it needs to consume part of the energy itself, and therefore can not generate particularly strong mechanical supercharger driving force, especially at high speeds, which affects the increase the engine speed.

Benefits: good response there is no turbo lag can be a steady stream of torque can be output at any time.

drawbacks: high rotation speed will produce a large amount of friction, thus affecting the speed increase, and noisy.

on behalf of models: Beijing Benz E200K Land Rover Range Rover Sport

gasoline direct injection (FSI) FSI Fuel Stratified Injection is the abbreviation prefix, which means fuel stratified injection. Fuel injection technology is a stratified lean burn engine technology. What is lean? As the name suggests is the low content of a gasoline engine in the gas mixture, the ratio of fuel and air up to 1:25 or more. It is characterized by a variable eddy current has been generated in the intake port, the intake air flow vortex form the best morphology enter the combustion chamber in a hierarchical manner to promote filling the mixed gas is concentrated around the spark plug located at the center of the combustion chamber.

gasoline direct injection (FSI) FSI Fuel Stratified Injection is the abbreviation prefix, which means fuel stratified injection. Fuel injection technology is a stratified lean burn engine technology. What is lean? As the name suggests is the low content of a gasoline engine in the gas mixture, the ratio of fuel and air up to 1:25 or more. It is characterized by a variable eddy current has been generated in the intake port, the intake air flow vortex form the best morphology enter the combustion chamber in a hierarchical manner to promote filling the mixed gas is concentrated around the spark plug located at the center of the combustion chamber.

advantages: a substantial increase in the fuel efficiency of the economy while increasing engine power.

disadvantages: very stringent requirements on oil.

Representative vehicle: Audi A4 2.0T Audi A62.0T

aluminum engine The biggest difference of two materials is the weight of the engine, the engine than the aluminum alloy iron half the weight of the engine can be light. Originally the total weight of the car is not high, but the proportion of share engine can not be ignored, the most direct effect of weight loss is easy to enhance fuel performance. And the weight of the engine is directly affect vehicle performance, since the plurality of front-wheel drive cars generally, such as excessive weight front cabin will cause excessive turning of the vehicle steering, and braking distance will be longer.

aluminum engine The biggest difference of two materials is the weight of the engine, the engine than the aluminum alloy iron half the weight of the engine can be light. Originally the total weight of the car is not high, but the proportion of share engine can not be ignored, the most direct effect of weight loss is easy to enhance fuel performance. And the weight of the engine is directly affect vehicle performance, since the plurality of front-wheel drive cars generally, such as excessive weight front cabin will cause excessive turning of the vehicle steering, and braking distance will be longer.

Advantage: half light engine weight, can reduce fuel consumption and improve handling performance.

Disadvantages: Aluminum materials are expensive.

Representative vehicle: Audi qida SWIFT Swift the A8

art variable valve timing (VVT-i VECT) Technical engine variable valve timing (VVT , Variable Valve Timing) in recent years is graduallyApplied on modern cars is a slow drift in the new technology, the engine with variable valve timing intake charge can be increased, so that the volumetric efficiency increases, the engine torque and power can be further improved.

art variable valve timing (VVT-i VECT) Technical engine variable valve timing (VVT , Variable Valve Timing) in recent years is graduallyApplied on modern cars is a slow drift in the new technology, the engine with variable valve timing intake charge can be increased, so that the volumetric efficiency increases, the engine torque and power can be further improved.

advantages: a substantial increase in the fuel efficiency of the economy while increasing engine power.

disadvantages: very stringent requirements on oil.

Representative models: Honda Accord Honda CR-V Toyota Corolla oulande new Mazda 6 BMW 325

The rotary engine of the interior space of the housing (or trochoidal chamber) is always divided into three studios. During the movement of the rotor, the three working chamber volume changes constantly, have been completed trochoidal intake air cylinder, compression, combustion and exhaust four processes. Each process is placed at different positions in the cylinder is linear, which is significantly different from the reciprocating engine.

The rotary engine of the interior space of the housing (or trochoidal chamber) is always divided into three studios. During the movement of the rotor, the three working chamber volume changes constantly, have been completed trochoidal intake air cylinder, compression, combustion and exhaust four processes. Each process is placed at different positions in the cylinder is linear, which is significantly different from the reciprocating engine.

Advantages: High fuel economy, the engine structure is simple, small vibration rate.

drawbacks: not high durability, high fuel consumption, high processing costs.

Representative models: Mazda RX-8

boxer engine boxer engine, the engine crankshaft evenly distributed on both sides of the piston, the horizontal direction left and right movement. Reduce the overall height of the engine, to shorten the length, the center of gravity of the vehicle decreases, more stable vehicle running, the engine is mounted on the center line of the vehicle, the torque generated by the piston on both sides cancel each other out, greatly reduces vibration of the vehicle during traveling, it greatly enhance the engine speed, reduce noise.

boxer engine boxer engine, the engine crankshaft evenly distributed on both sides of the piston, the horizontal direction left and right movement. Reduce the overall height of the engine, to shorten the length, the center of gravity of the vehicle decreases, more stable vehicle running, the engine is mounted on the center line of the vehicle, the torque generated by the piston on both sides cancel each other out, greatly reduces vibration of the vehicle during traveling, it greatly enhance the engine speed, reduce noise.

Advantages: significantly reduce the vibration of the vehicle is traveling, the engine speed greatly enhance, reduce noise.

drawbacks: each part of the engine design and production processes require quite demanding.

Representative models: Impreza WRC 911

common rail diesel injection system The common-rail diesel injection system generated injection pressure and injection of one another completely separate. Solenoid valve controlled injector replaces the traditional mechanical injectors, the fuel pressure in the fuel rail is generated by a radial piston high pressure pump, regardless of the engine rotation speed of pressure, Can be set freely within a certain range.

common rail diesel injection system The common-rail diesel injection system generated injection pressure and injection of one another completely separate. Solenoid valve controlled injector replaces the traditional mechanical injectors, the fuel pressure in the fuel rail is generated by a radial piston high pressure pump, regardless of the engine rotation speed of pressure, Can be set freely within a certain range.

Advantages: very good economic efficiency, and good low speed torque available power.

drawbacks: noise and vibration generated by the engine larger.

Representative vehicle: Audi Bora 1.9TDI A62.5TDI Huatai Terracan 2.9CRDi

9, the basic theory

The gasoline gasoline engine energy into kinetic energy to drive the car, the easiest way is to get kinetic energy by burning gasoline inside the engine. Therefore, the car engine is an internal combustion engine in an internal combustion engine —- happen.

There are two points to be noted

1. There are also other types of internal combustion engines, such as diesel engines, gas turbines, each have their own advantages and disadvantages.

2. There are also external combustion engine. In the early trains and ships with steam engines is a typical external combustion engine. Fuels (coal, wood, oil) outside the engine combustion to generate steam, and steam into the interior of the engine to generate power. Many high efficiency internal combustion engines, but also much smaller than the external combustion engine of the same power than the external combustion engine. So, Hyundai Motor without steam engine.

In contrast, the internal combustion engine more efficient than external combustion, cheaper than the price of gas turbines, electric vehicles easy to add fuel ratio. These advantages make the most of the modern cars use a reciprocating internal combustion engine.

Combustion is a key

generally used automobile engine 4-stroke.

4-stroke are: intake, compression, combustion and exhaust. Four complete process, a complete engine cycle (two turns).

appreciated that a four-stroke

of the piston, its associated piston rod and a crankshaft made, as follows:

1. Beginning at the top of the piston, the intake valve opens, downward movement of the piston, the intake air mixture

2. To the top of the piston movement to compress the oil and gas mixture, making the explosion more powerful.

3. When the piston reaches the top of the spark discharge of the spark plug to ignite the air mixture, so that the blast piston downwards again.

4. Piston reaches the bottom, the exhaust valve opens,Upward motion of the piston, the exhaust gas discharged from the exhaust pipe from the cylinder.

Note: the final movement of the engine rotation is generated, the linear reciprocation of the pistons into rotation by a crankshaft ultimately, so as to drive the car tires.

Engine the number of cylinders The core component of the engine is a cylinder, the piston reciprocates within the cylinder as described above is a single cylinder movement, the practical application of the engine there are a plurality of cylinders (four-cylinder, 6-cylinder, 8-cylinder more common). We usually through the arrangement of the cylinders of the engine classification: in-line, V or horizontally opposed (Of course, now there is the Volkswagen Group’s W-type, is actually composed of two V).

Engine the number of cylinders The core component of the engine is a cylinder, the piston reciprocates within the cylinder as described above is a single cylinder movement, the practical application of the engine there are a plurality of cylinders (four-cylinder, 6-cylinder, 8-cylinder more common). We usually through the arrangement of the cylinders of the engine classification: in-line, V or horizontally opposed (Of course, now there is the Volkswagen Group’s W-type, is actually composed of two V).

such that the engine different arrangements have their own advantages and disadvantages in the smoothness, appearance and manufacturing costs, provided on the respective cars.

the displacement of

and the compressed gas mixture for combustion in the combustion chamber, the piston reciprocates, you can see the change in combustion chamber volume, the maximum and minimum difference is the displacement in liters (L ) or milliliters (CC) is measured. Car emissions generally between 1.5L ~ 4.0L. Displacement per cylinder 0.5L, 4 cylinder 2.0L displacement, if the V-type 6-cylinder arrangement, that is, V6 3.0 liter. In general, it represents the size of the displacement of the engine power.

or the number of cylinders is increased to increase the volume of the combustion chamber of each cylinder can get more power.

engine is by mixing combustible gas and combustion air to the movement, if the engine can not get enough fresh air, the combustion of combustible gas will not entirely, the result is that fuel economy deteriorates, engine power down. Modern engine speed is high, generally can reach more than 4500 revolutions per minute, to complete a work cycle only takes about O.OO5 seconds, the traditional two-valve has not qualified in such a short period of ventilation tasks, thereby limiting the improve engine performance, the solution only to expand out of the gas space, with a larger space to gain time. The multi-valve technology is the best way to solve, it appears that the overall engine quality has been improving on nature.

The so-called multi-valve per cylinder engine technology is more than two valves, particularly inlet 2 has a 2 into 2, 3, etc. are arranged into two types. But the number of excessive intake air valveWill fall, and will make the structure more complex, high processing requirements, increased manufacturing costs, but not good. So now the engine is widely used is the 3-5 valve structures, in particular four-valve used more widely, and the engine on the high-end cars modern almost all uses a multi-valve structure, it has become a technology of modern cars indicator, e.g., on the use of 5 Jetta valve technology, which enables the engine with the same displacement, the output larger power.

Engine Other parts of the engine

Engine Other parts of the engine

camshafts: controlling the intake and exhaust valves opened and closed

spark plugs: The spark plug ignites a spark discharge air mixture, so that explosion. Sparks must be released at the appropriate time.

valves: inlet, outlet valves are opened to suck and discharge the exhaust gas air mixture at the appropriate time. The compression and combustion, the two valves are closed, to ensure sealing of the combustion chamber.

Piston Ring: Presented sealed in the cylinder wall and the piston:

1. Prevented during compression and combustion air mixture and exhaust leakage into the oil tank.

2. Prevent the lubricating oil into the combustion cylinder.

Most of “burn oil” car is too old because the engine, the piston ring seal is no longer induced (tailpipe take smoke)

of the piston rod: connecting a crankshaft and a piston ring, the piston and the crank movement while maintaining each .

the lubricating oil grooves: surrounds the crankshaft, there are a considerable number of the oil

10, the engine maintenance

a, maintenance three filter

three filter means: fuel filter clean, air filter and oil filter.

plays a role in the filtering three filter oil, air and fuel in the automobile engine, thereby protect the engine, but also improve the efficiency of the engine plays the role. Engine maintenance in three filter maintenance is essential.

Second, the periodic cleaning automotive crankcase

When the engine during operation, high-pressure combustion chamber unburned gas, sulfur, water, and nitrogen acidsOxide through a gap between the piston ring and cylinder wall into the crankcase, with long-term wear parts, generation of metal powder mixed together, the formation of sludge. Therefore, regular cleaning of the crankcase, keeping the internal engine cleanliness is necessary.

Third, regular oil

regardless of high or low quality grade lubricating oil changes in the course of mass will, therefore in order to avoid failure, conditions of use should be based on periodic change oil and the oil is moderate. Therefore, engine maintenance, be sure to use good oil.

Fourth, the regular cleaning of automotive fuel system

engine maintenance, fuel system must give good care. Automotive fuel systems regularly to do clean-up, you can control soot formation, so that the engine in the best condition.

Fifth, regular cleaning tank car

automotive engine water tank rust, scale is a very common problem. Scale and rust will impede the flow of coolant in the cooling system, reduces the heat dissipation effect, thereby resulting in engine overheating, even cause engine damage. Therefore, regular cleaning tank is very important.